The quality of PCBs has always been our most concerned problem when selecting PCB assembly factory. The one-pass rate do not only affects the cost, but also directly affects the customer's trust in the supplier. Many factories will think that the quality problems of PCBs are caused by problems in the manufacturing process. In fact, they are not. We need to evaluate and audit many problems before production, in order to avoid unexpected problems in the manufacturing process. This is also a test of the strength of a PCB assembly factory. If a factory does not have a complete processing process, it may not be able to find the problem. That is why the quality is poor. How to control PCBs quality? Now Shenzhen 1942 Technology Co., LTD will share some tips with you, hope they are helpful.

1.Pre-review Before Production.

For new products before producing, the engineering department must organize the personnel of the production department, the purchasing department and the quality department to hold a new product introduction meeting, and the business department shall lead all customer needs and delivery dates.

2. BOM Review

Check the customer supplied PCB documents, drawings and coordinates in advance, check the BOM list, optimize the material description, check the P/N, package, quantity and designator, and improve the brand specification and material information.

3. PCBs Processing Review

Formulate new material/ new process/ new design operation requirements, review and confirm the documents, and check whether the material and PCB specifications meet the requirements for operation, and the requirements for material baking conditions.

4. Inspection of PCBA raw materials

Implement the sample management of new material samples to ensure that the quality of material samples can meet the requirements of products, and serve as the basis for purchase orders and incoming inspection.

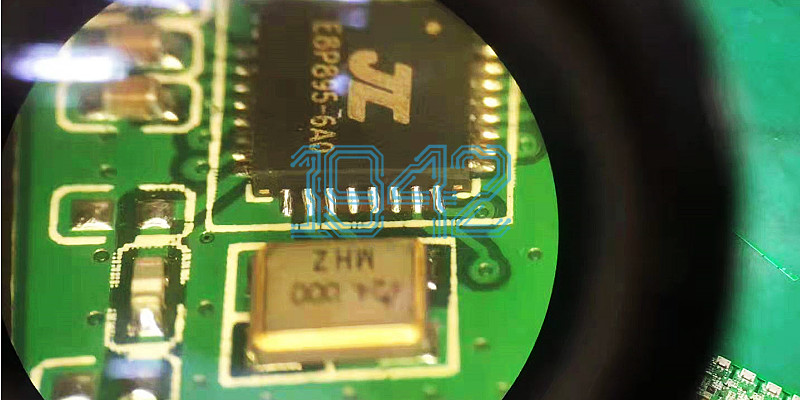

5. Components Incoming Quality Check

Check every components to ensure product quality. Measure the resistors and capacitors’ value according to the BOM list, Check the silkscreen of Class A Components, check the size of components pins and PCB Pad, check whether the pins are deformed and oxidized, and inspect the appearance of PCB.

6. Tooling Verification

The engineering department shall provide drawings and specifications for newly opened stencil, testing fixture, oven fixture etc. The process and material requirements shall be indicated.

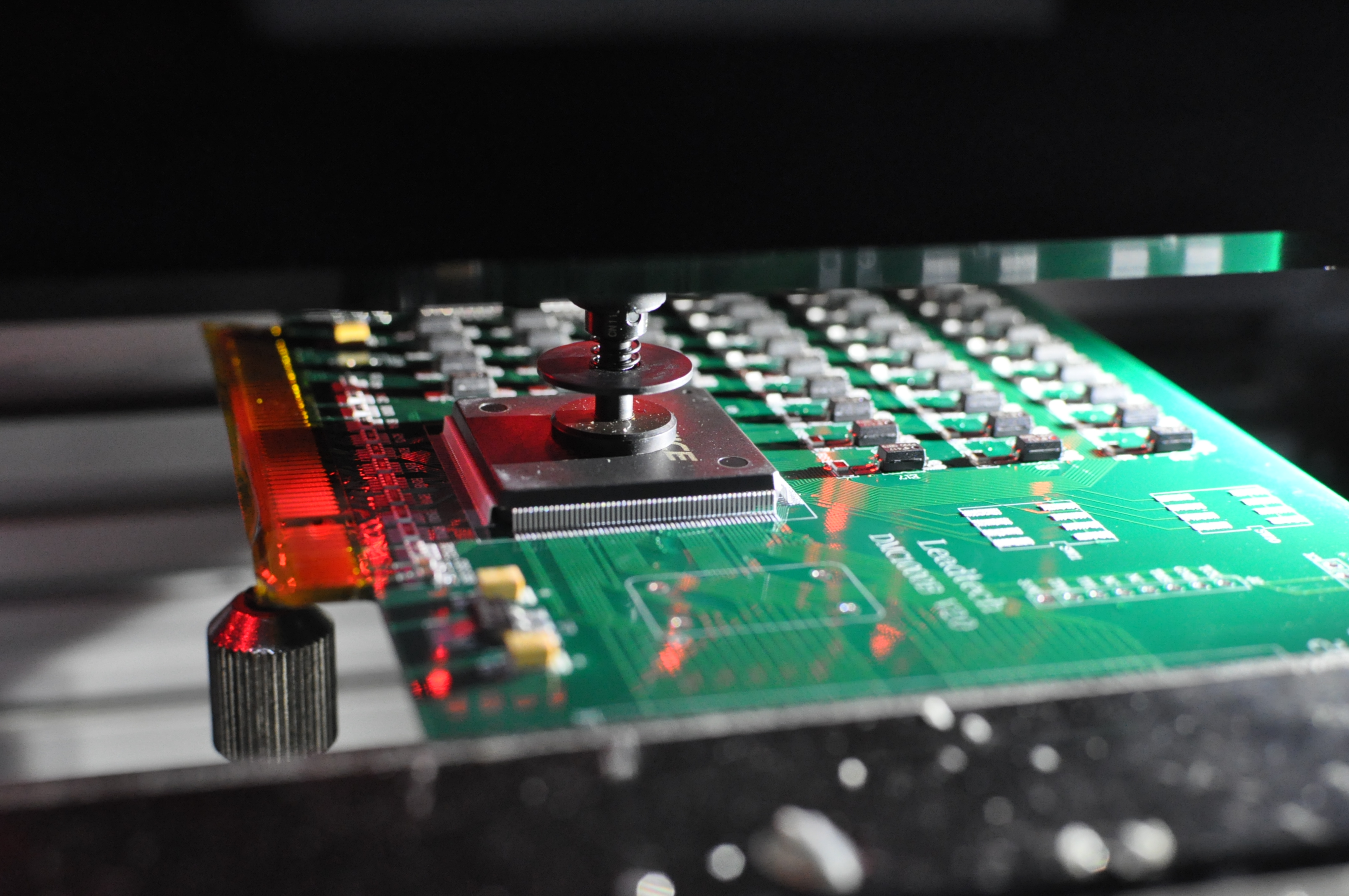

7. Oven Temperature mornitoring

The actual soldering temperature of PCBs must be tested by the 9-channel oven temperature tester is combined with the PCBs, temperature based on 260 ° C<10S, 235 ° C 60-90S.

8. First Article Inspection

Automatically generate detection program by integrating BOM, coordinates and first article image of HD scanning. Quickly and accurately detect components, automatically determine results, generate first article reports, and enhance quality control.

9. The full process Inspection

A PCBs factory equipped with testing equipment, which is the basis to ensure the quality of PCBs. Our production lines equipped with first article testing detector, SPI, Online and Off-line AOI ,and X-Ray for BGA soldering inspection .

2024-06-03

2024-06-03