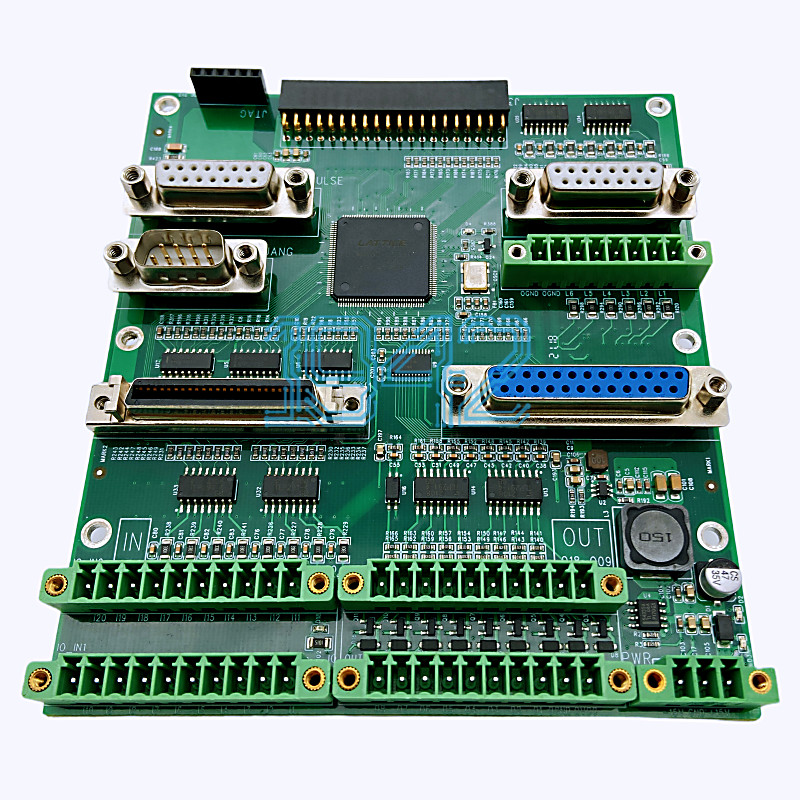

Point:246

Components type:70

PCB size: 130mm*110mm

Minimum package size of resistance capacitance sensing: 0402

Minimum device pin spacing:0.65

Welding mode:Reflow soldering for double sides+ Wave soldering.

Manufacturing process: PCB producing+components procurement+assembly

Shenzhen 1942 Technology Co., LTD is a professional PCBs manufacturer, 7 SMT production lines ,5000㎡ factory

Main bussiness : PCB design , SMT, DIP, compnents soucing, function test , PCBA coating, PCBA failure analysis.

PCBs applications:

medial equipment PCB& PCBA

industrial control PCB$PCBA

IOT ( internet of things ) PCB &PCBA

drones PCB & PCBA

Video equipment PCB &PCBA

…………

The total number of front and back surface mount components is 246

The amount types are 70

The outer diameter of PCB is 095mm*095mm

The minimum package size of surface mounted components is 0402

The minimum pin spacing of surface mount components is 0.65mm

Components are soldered by double-sided reflow soldering machine

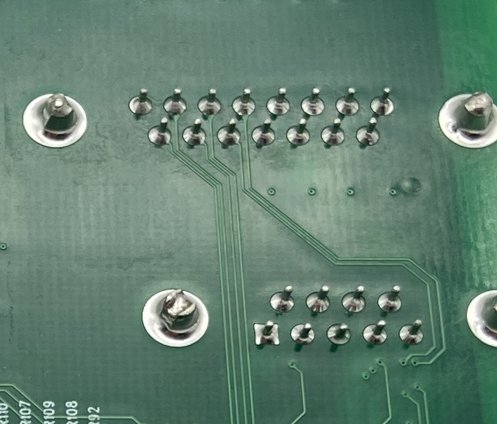

Though hole components soldered by wave soldering machine

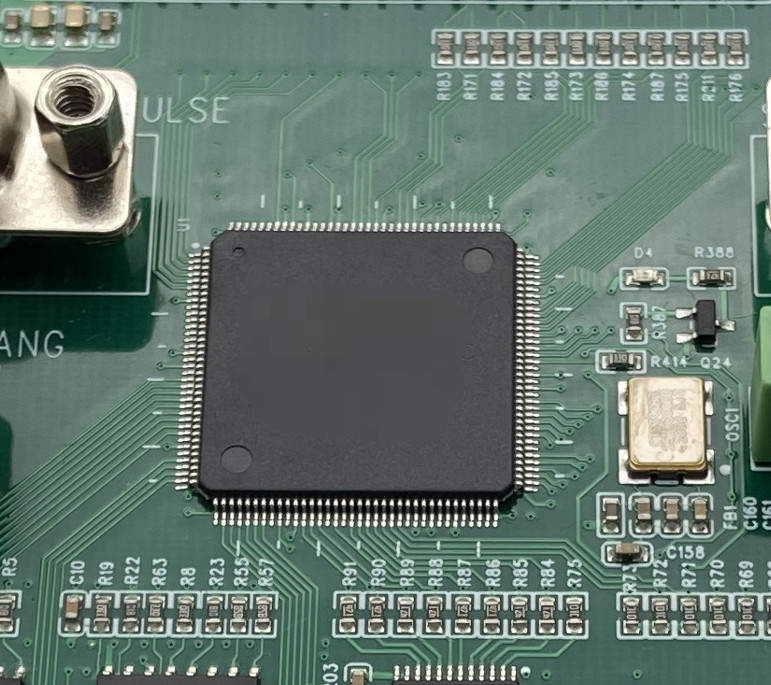

IC mounting

12-zone dual-track hot air reflow soldering oven, Each solder dot is exquisite and beautiful. Surface mount technology is also an art

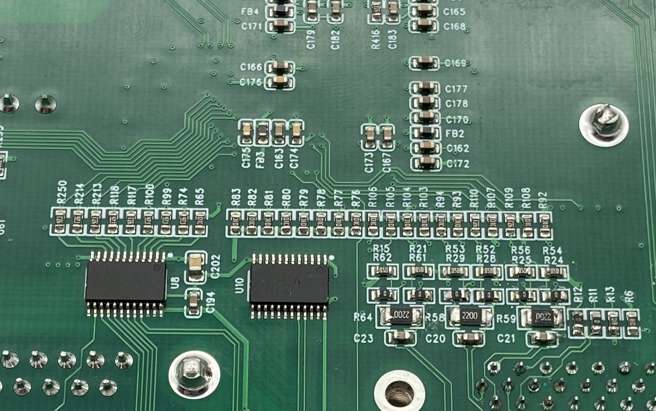

R&C Series Mounting

Though Hole components sodering

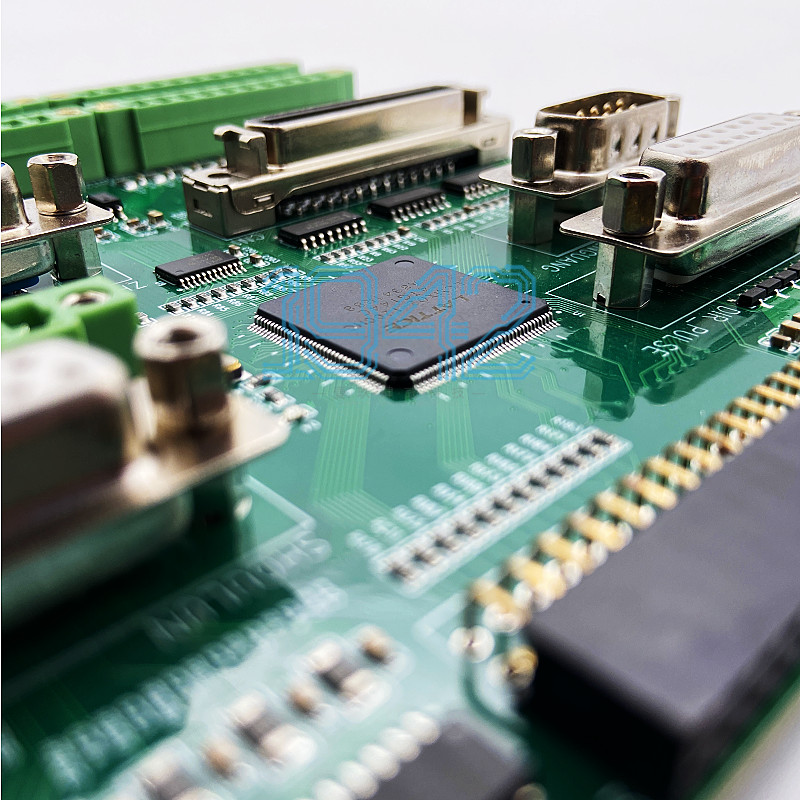

The most important thing of the motion controller is its main chip. The connection between the main board and the external computer is relatively simple, the exploitability is high, and the general performance of the software code is good. Under these characteristics, the main chip and programming of the controller are very important, which directly affects the market positioning and final price of the finished product to a certain extent.

While developing and designing this motherboard for our customers, our company conducted detailed communication with the customer's software development engineers, determined the circuit design and the selection of the main chip, and finally made the motion controller motherboard to the satisfaction of our customer.