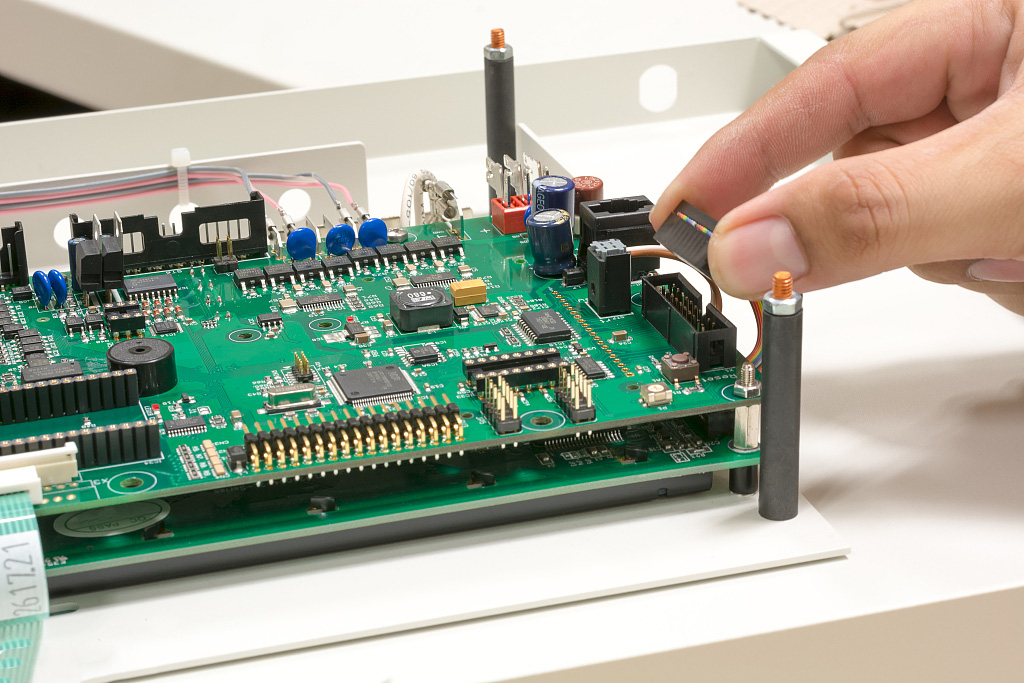

1943 stands as your premier destination for PCB assembly services in China, providing an all-encompassing solution that caters to your project’s scale and complexity. Whether you’re in the early stages of prototyping or preparing for mid-scale production, our services are designed to meet your diverse needs seamlessly.

Our surface mount technology (SMT) assembly service boasts precision and efficiency, ensuring the accurate placement of components ranging from standard resistors to sophisticated integrated circuits. We excel in ball grid array (BGA) assembly, showcasing our proficiency in handling complex components with finesse, ultimately contributing to optimal performance.

Through-hole assembly is seamlessly integrated into our comprehensive suite of services, accommodating a variety of component types and ensuring robust connections. Our expertise extends to mixed assembly, where we adeptly combine SMT and through-hole technologies to meet the unique requirements of your design.

In addition to these capabilities, we specialize in rigid-flex printed circuit board assembly, providing a flexible and durable solution for applications demanding intricate and dynamic designs.

Please click the question to get the answer.

Printed circuit board assembly, also called PCBA, is the process of soldering or assembling electronic parts to a printed circuit board (PCB).

Surface Mount Technology, or SMT, is a printed circuit board assembly process for SMD electronic components. SMD components do not have leads or legs. They are mounted on the surface of the circuit board.

It is also called "thru-hole." It is the mounting scheme used for electronic components that involves the use of leads on the components that are inserted through holes drilled in printed circuit boards.

A rectangular or square array of solder balls placed on one surface.

An electronic device made for mounting or placing electronic components directly onto the surface of printed circuit boards (PCBs).

Package on Package (PoP) is an integrated circuit packaging method that allows for higher component density in devices, such as mobile devices. It involves stacking two or more packages vertically via a standard interface to route signals between them.

Common inquiries often cover minimum order quantities, response times, and specific services related to manufacturing.

PCBA (Printed Circuit Board Assembly): Involves assembling individual components onto a printed circuit board (PCB) to create a functional unit.

CCA (Circuit Card Assembly): Comprises multiple PCBs assembled together to form a complete electronic circuit.

Let the products quickly and stably realize marketization and become the global electronic intelligence innovation enabler