Project Management for First-to-Demo Prototypes and Low-Volume PCB Assemblies

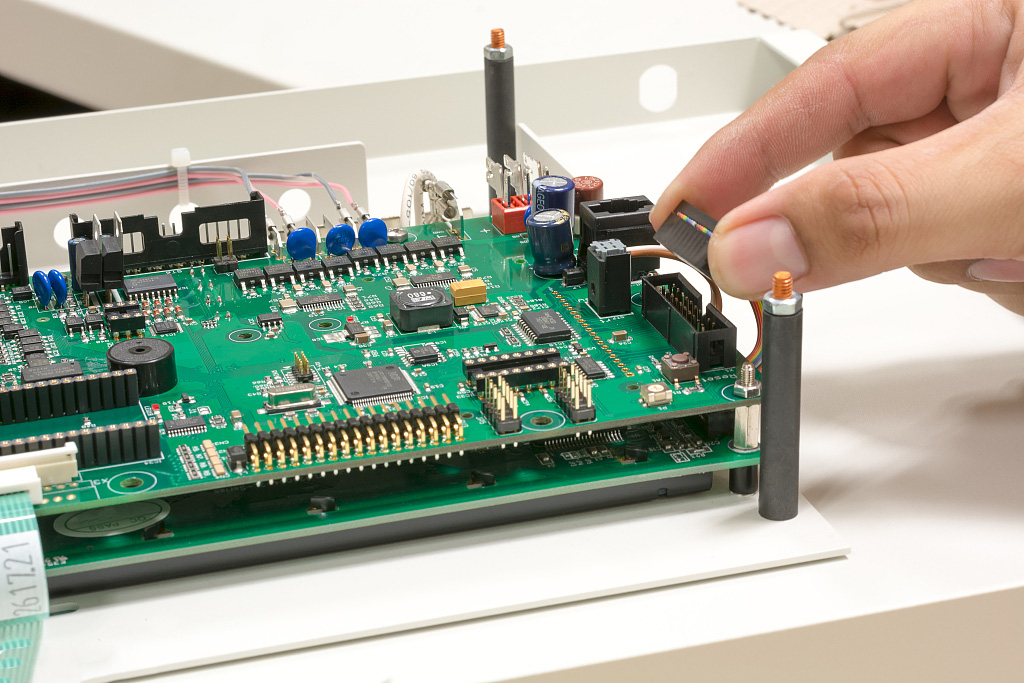

At 1943, our NPI services seamlessly connect product design with stable SMT and PCBA mass production. We validate manufacturability, optimize assembly processes, and ensure your product is fully prepared for efficient volume manufacturing.

Key Capabilities:

With structured NPI support integrated into SMT and PCBA manufacturing, we help reduce production risk, improve product reliability, and accelerate time-to-market.

1943 stands as your premier destination for PCB assembly services in China, providing an all-encompassing solution that caters to your project’s scale and complexity. Whether you’re in the early stages of prototyping or preparing for mid-scale production, our services are designed to meet your diverse needs seamlessly.

Our surface mount technology (SMT) assembly service boasts precision and efficiency, ensuring the accurate placement of components ranging from standard resistors to sophisticated integrated circuits. We excel in ball grid array (BGA) assembly, showcasing our proficiency in handling complex components with finesse, ultimately contributing to optimal performance.

Through-hole assembly is seamlessly integrated into our comprehensive suite of services, accommodating a variety of component types and ensuring robust connections. Our expertise extends to mixed assembly, where we adeptly combine SMT and through-hole technologies to meet the unique requirements of your design.

In addition to these capabilities, we specialize in rigid-flex printed circuit board assembly, providing a flexible and durable solution for applications demanding intricate and dynamic designs.

7 automatic SMT production lines

Production capacity: 15.32 million soldering spot per day

Proportion of capacitance and resistance loss: 0.3%

Mounting general FR-4 PCB, FPC and FPCB

Minimum package : 0201chip / 0.35 pitch BGA

Minimum mounting accuracy :± 0.04mm

IC mounting accuracy: ± 0.03mm

PCB size: L50 * W50mm - L510 * w460mm

PCB thickness: 0.3mm-4.5mm

At 1943, we provide reliable material procurement services to support stable SMT and PCBA production. Our team manages component sourcing, verification, and supply coordination based on your BOM requirements.

Key Services:

With structured material procurement management, we help ensure stable supply, controlled quality, and efficient production readiness.

At 1943, we ensure every product meets strict quality and performance standards through integrated testing and assembly solutions.

PCBA Test:

Box Build Assembly:

From verified PCBA to fully assembled product, we deliver reliable and ready-to-use manufacturing solutions.

Enterprise strength

Enterprise strength

Shenzhen 1943 Technology Co., Ltd., established in 2015, is a high-tech enterprise focusing on

industrial PCBs manufacturing, providing customers with one-stop solutions such as PCB design, SMT

patch, centralized device purchase, test assembly, failure analysis and so on.

The company has 5000 ㎡ independent plant, 7 high-end SMT production lines and more than 120

production personnel.

Raw materials, technology, quality control, delivery and service

Fast and reliable PCBA service provider

The enterprise has passed ISO9001:2015 and ISO:13485 international standard quality management system and ipc-a-610 level II and III certification, covering the whole process of product R & D, raw material management, standardized production, quality inspection and after-sales service.

The production line is equipped with high-end automatic production equipment and full-automatic optical detection instruments, whole process quality control, high precision and high yield. Carry out quality inspection and control in each process to avoid the outflow of defective products.

Products

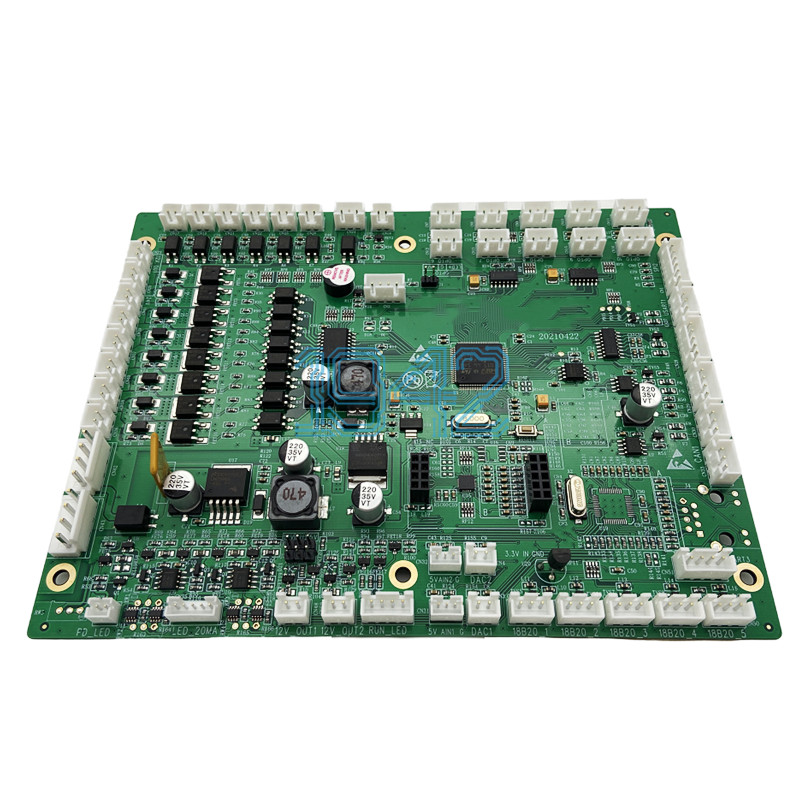

Products1943 provides customers with high-precision SMT patch processing services, equipped with seven high-speed SMT patch production lines, and has long provided PCBA processing and manufacturing services to many customers at home and abroad.

Our service cases mainly include industrial control, medical electronics, communication Internet of Things, security equipment, and instrumentation industries, and the service content covers the entire PCBA processing and manufacturing process.

Including [PCB board making, component procurement, SMT patch processing, DIP plug-in, test assembly, three-proof paint coating, coding, marking] and other processes.

Through our professional services, products can obtain real production supply and stable and reliable quality dual guarantees.

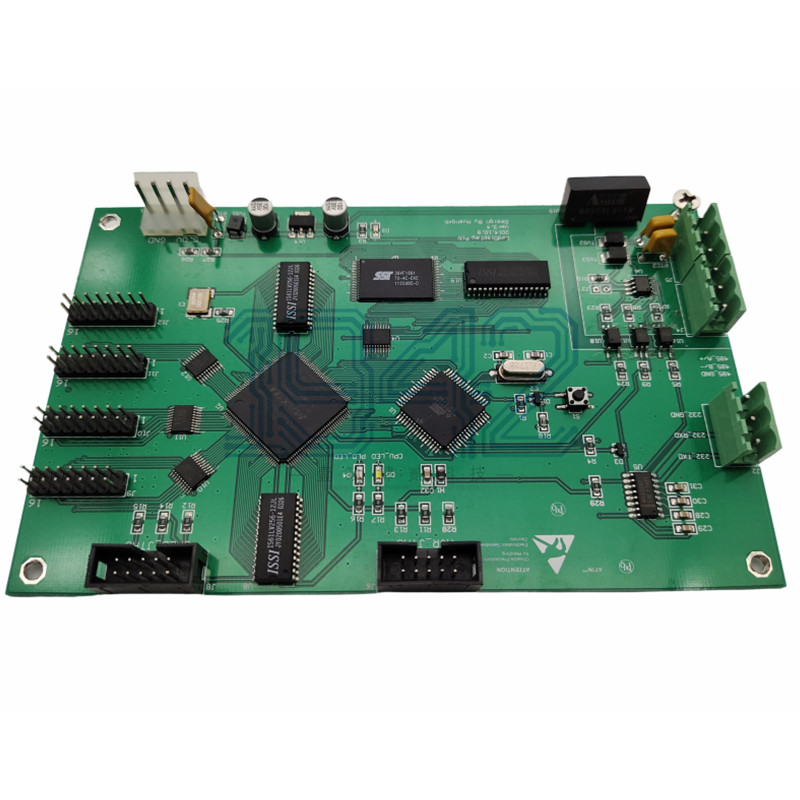

Point:142

Types of components:54

PCB size: 175*132mm

Soldering process:Reflow soldering for double side + Wave soldering.

Full processes: PCB producing + components procurement + assembly

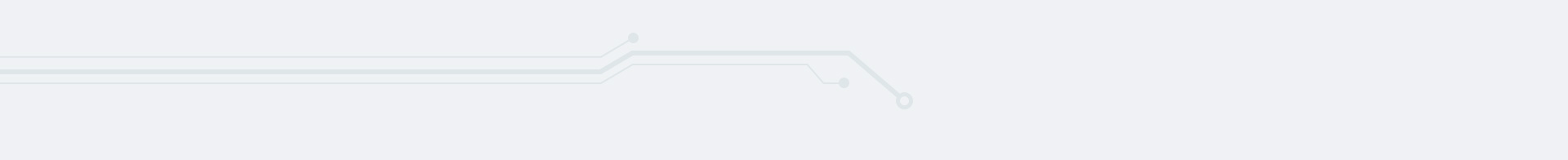

Point:149

Types of components:82

PCB size: 144*137mm

Soldering process:Reflow soldering for double side + Wave soldering.

Full processes: PCB producing + components procurement + assembly

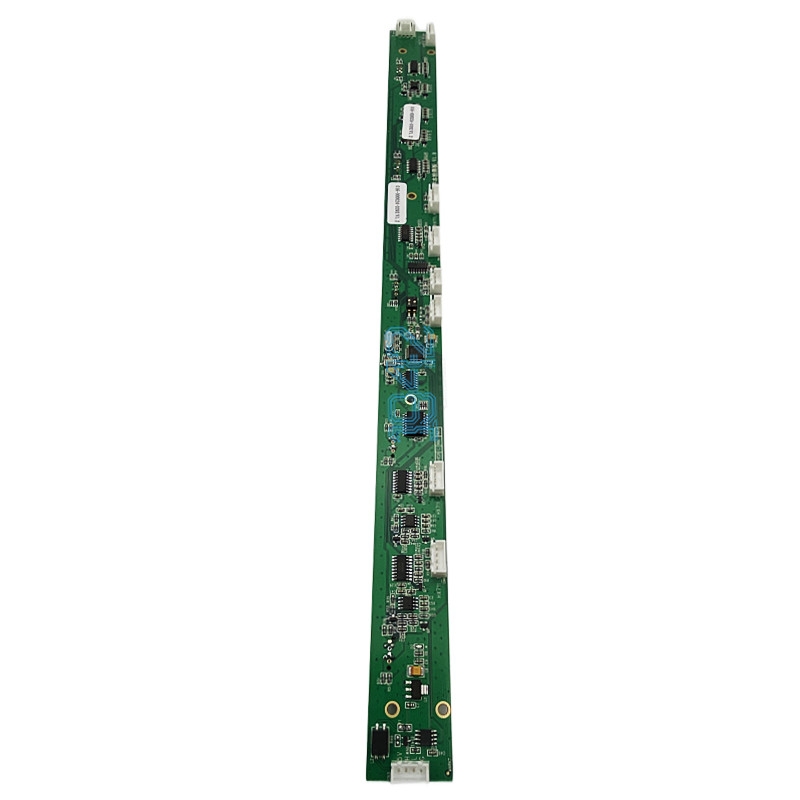

Point:146

Types of components:64

PCB size: 322*54mm

Soldering process:Reflow soldering + Selective wave soldering

Full processes: PCB producing + components procurement + assembly

Point:278

Types of components:85

PCB size: 173*146mm

Soldering process:Reflow soldering + Selective wave soldering

Full processes: PCB producing + components procurement + assembly

News

News

Let the products quickly and stably realize marketization and become the global electronic intelligence innovation enabler